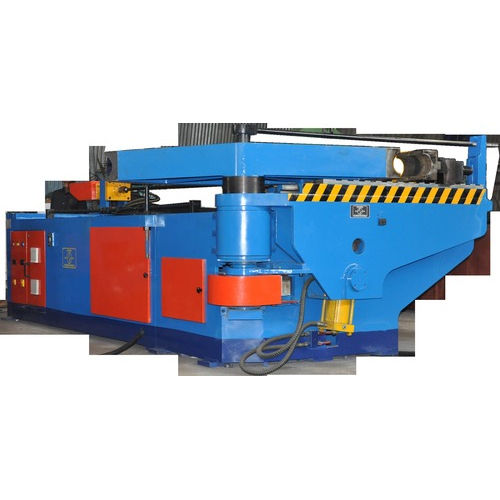

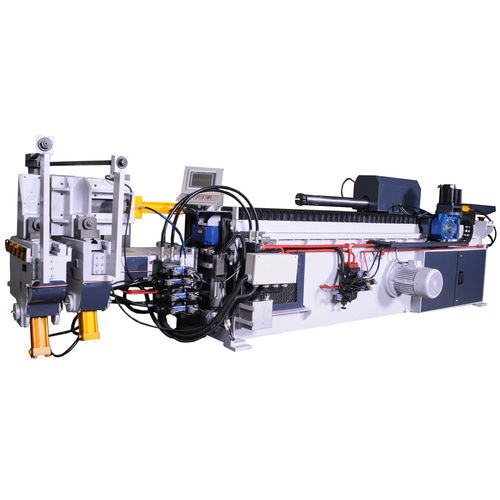

CNC Pipe Bending Machines

Product Details:

- Place of Origin India

- Capacity Up to 40 mm pipe diameter

- Bending Strength Max. 40 mm (Pipe OD)

- Raw Material Mild Steel, Stainless Steel, Copper, Aluminum

- Bend Radius 1.5D Min. (customizable)

- Color Blue & Grey

- Production Capacity Up to 800 bends/hour (depending on pipe size and thickness)

- Click to View more

CNC Pipe Bending Machines Price And Quantity

- 1 Unit

CNC Pipe Bending Machines Product Specifications

- Blue & Grey

- 380V / 415V

- 1440 rpm

- 0 to 190

- 3200 x 1100 x 1300 mm

- Three Phase

- Automatic Pipe Bender

- Up to 800 bends/hour (depending on pipe size and thickness)

- CNC Automatic

- Industrial Pipe Bending

- 7.5 kW

- Max. 40 mm (Pipe OD)

- Mild Steel, Stainless Steel, Copper, Aluminum

- India

- Up to 40 mm pipe diameter

- Precision Pipe Bends

- 1500 kg

- CNC Pipe Bending Machine

- NEW

- 1.5D Min. (customizable)

CNC Pipe Bending Machines Trade Information

- 10 Unit Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

Being a well established organization, we bring forth an excellent assortment of that is commonly used for bending wires in electrical industry. Our offered machine is extensively admired in the market for its long service life and smooth functioning. This machine is provided in enormous models and technical specifications for our clients to choose from. Furthermore, offered Bending Machine is fabricated under the supervision of brilliant professionals using quality approved components and advanced technology in tune with set market standards.

Features:

-

Low maintenance

-

Trouble-free operation

-

Anti-corrosive body

-

High functionality

Exceptional Bending Precision

With its advanced CNC control, the automatic pipe bender ensures highly accurate and repeatable bends, accommodating pipe diameters up to 40 mm OD. Each bend stays within tight tolerances and angles ranging from 0 to 190, enhancing output consistency for demanding industrial requirements.

Robust Construction and Capacity

Designed for continuous industrial use, the machine features a durable structure weighing 1500 kg, powered by a 7.5 kW motor running at 1440 rpm. Its capacity to bend up to 40 mm pipes with a customizable bend radius addresses diverse application needs, supporting various metals like stainless steel and aluminum.

Impressive Production Efficiency

This CNC automatic pipe bending machine can achieve up to 800 bends per hour, making it ideal for high-volume production lines. The automation not only reduces manual labor but also increases throughput and operational safety, making it a cost-effective solution for manufacturers.

FAQs of CNC Pipe Bending Machines:

Q: How does the CNC Automatic Pipe Bender operate?

A: The machine utilizes advanced CNC control to accurately guide the bending process, automating pipe positioning, feeding, and bending angles. Operators input the desired parameters, and the system ensures precision bends without manual intervention.Q: What types of materials can this machine bend?

A: It is suitable for a range of materials, including mild steel, stainless steel, copper, and aluminum. The robust design and customizable settings accommodate diverse industrial application requirements.Q: When is using a CNC automatic pipe bender most beneficial?

A: This machine is most advantageous for high-volume production environments or projects requiring repeated, complex bends with strict tolerances, ensuring efficiency and reducing the probability of human error.Q: Where is this CNC pipe bending machine manufactured?

A: The machine is manufactured and supplied in India, ensuring reliable quality and robust engineering as per industrial standards.Q: What is the maximum output capacity of the machine?

A: Depending on the pipe size and thickness, it can perform up to 800 bends per hour, making it ideal for industrial-scale production where efficiency is crucial.Q: How does the bending process maintain precision and consistency?

A: The CNC automation system handles every step of the bending process, from pipe feeding to angle execution, ensuring each bend matches programmed specifications with high repeatability and minimal deviation.Q: What are the key benefits of using this pipe bending machine in industrial applications?

A: Users gain from consistent, high-quality bends, reduced labor costs, enhanced safety, and the ability to handle a wide range of pipe materials and sizes, all within a fast production cycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+