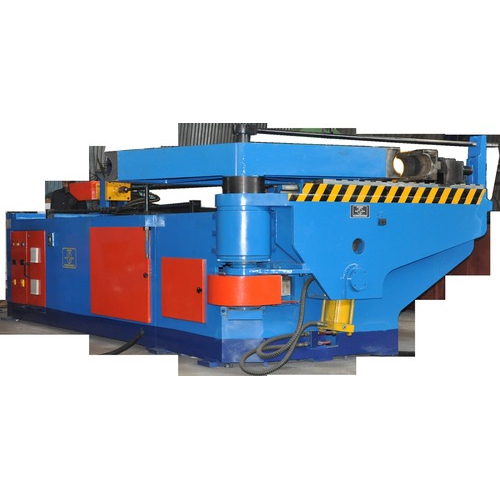

Single Axis Pipe Bending Machine

Product Details:

- Dimension (L*W*H) 1700 x 700 x 1500 mm

- Phase Three Phase

- Output Smooth and Accurate Pipe Bend

- Power 3.5 kW

- Weight 500 kg

- Usage Industrial Pipe Bending

- Place of Origin India

- Click to View more

Single Axis Pipe Bending Machine Price And Quantity

- 250000.00 - 100000.00 INR/Unit

- 1 Unit

Single Axis Pipe Bending Machine Product Specifications

- 1700 x 700 x 1500 mm

- Three Phase

- Smooth and Accurate Pipe Bend

- 3.5 kW

- 500 kg

- Industrial Pipe Bending

- India

- Blue

- Single Axis

- Up to 60 kN

- 0 to 180

- 380V

- Pipe Bending Machine

- NEW

- Steel / Stainless Steel Pipes

- Pipe Diameter 10 mm to 75 mm

- 1440 RPM

Single Axis Pipe Bending Machine Trade Information

- 10 Unit Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

Under the strict supervision of our experienced professionals, we are offering the finest quality range of Single Axes Pipe Bending Machines that is primarily used in general engineering and automobile industry. These machines are made available in variety of models and technical specifications to meet clients necessities. The Single Axes Pipe Bending Machines provided by us are intricately manufactured at our highly advanced production unit using premium quality components and progressive technology in line with set international standards.

Features

-

Colour LCD Touch Panel for Data Entry and Editing

-

Operation mode-Manual/Semi auto/Fully Auto

-

15 bends program

-

Bend arm over ride switch to prevent bend arm/machine collision

-

Programming in in mm

-

Program Retrieval by Alphanumeric code, password

-

Hydraulic Mandrel Retraction

-

Online/Offline diagnosis mode

-

Built In Hydraulic Oil Cooling system

-

Clockwise Bending

Advanced Control for Precision Bending

The PLC panel enables intuitive control over the bending process, allowing operators to achieve perfect pipe angles with minimal effort. Integrated safety systems, including an emergency stop and overload protection, minimize operational risks and ensure consistent performance. This results in enhanced productivity and reduced error rates.

Customizable and Versatile Operation

Engineered for flexibility, the machine features customizable die sets to match various pipe sizes and materials, from SS and MS to copper and aluminium. Its dual operation modesfoot pedal or manualsuit different user preferences and workflow requirements, making it highly adaptable for various industrial applications.

Built for Industrial Reliability

Constructed with a sturdy blue steel body, the machine weighs 500 kg and is equipped with a hydraulic oil tank capacity of 60 litres. The strong motor (3.5 kW, 1440 RPM, three phase) ensures high performance for demanding, continuous operations. Its compact dimensions make integration into existing production lines straightforward.

FAQs of Single Axis Pipe Bending Machine:

Q: How does the PLC control system improve the bending process?

A: The PLC panel provides precise, programmable control over each bending operation, enabling operators to set and reproduce accurate angles with ease. This minimizes manual intervention and ensures consistent, high-quality pipe bends.Q: What materials and pipe sizes can this machine handle?

A: This machine is compatible with steel, stainless steel, mild steel, copper, and aluminium pipes. It supports pipe diameters from 10 mm up to 75 mm, with material thicknesses up to 6 mm, making it suitable for a wide range of industrial applications.Q: When should the emergency stop or overload protection be used?

A: The emergency stop should be activated immediately in any unsafe situation or operational irregularity. Overload protection automatically kicks in if the system exceeds safe pressure or force limits, helping protect both the machine and operator from potential damage or injury.Q: Where is this pipe bending machine typically installed?

A: Due to its robust construction and capacity, the machine is best suited for industrial workshops and manufacturing facilities that require frequent and precision pipe bending operations.Q: What is the process for changing the die set?

A: Changing the die set is straightforward: stop the machine, disengage the current die, and mount the required custom die set based on pipe size and shape specifications. Always ensure the machine is off during this process for safety.Q: How does operating with a foot pedal or manual mode benefit users?

A: Foot pedal operation enhances user comfort and efficiency, allowing hands-free control during repetitive tasks. Manual mode provides greater flexibility for complex or unique bending requirements, catering to specific user needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+